Magis Spa, Italy

The design process is mostly the same as usual. Drawing, 3D modelling, models, prototypes, back to modelling and drawing etc. The circle is the same, even if each project has its specific aspects in terms of conception. In this very case, what is surprising is that at the end of the very long and interesting drawing step, the chair was already very precise. For other projects, it may happen that the models make the project evolve. But is this case, the models, prototyping and rendering steps wer

e aimed at making the final result be close to the last drawings.

In this project, we made no models by ourselves, which is very rarely the case. But we sent information to Magis that had models be made and sent to us. Really in the project, the drawing was essential.

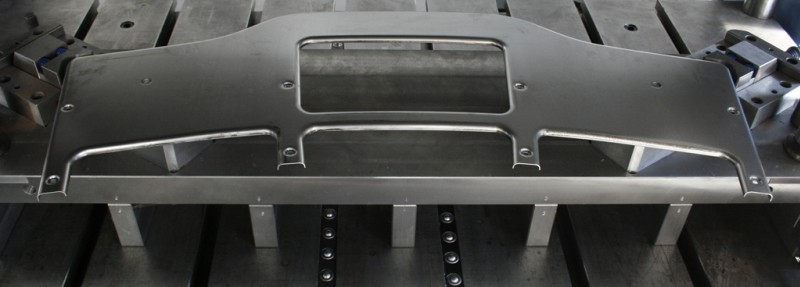

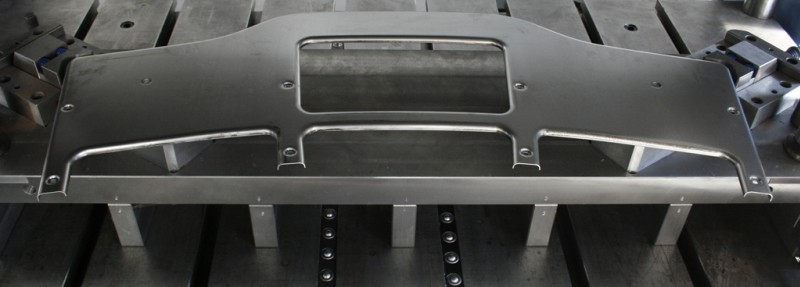

If the general process was very long, it is because it took a very long time to adjust all the details in terms of shape, comfort and finishing. There has been about 7-8 successive versions of the final prototype, being modified millimetre by millimetre to get the final version.